Vertex Software, Inc . announced that they have been selected as the software provider for the plants of Deere & Company, the world’s leading manufacturer of agricultural, forestry and other heavy equipment.

John Deere employees will use Vertex to access plant status, equipment maintenance needs, analytics, predictive scheduling and real-time equipment performance information. They can access content on any computing device in seconds, including tablets, laptops and smartphones, the new partners note.

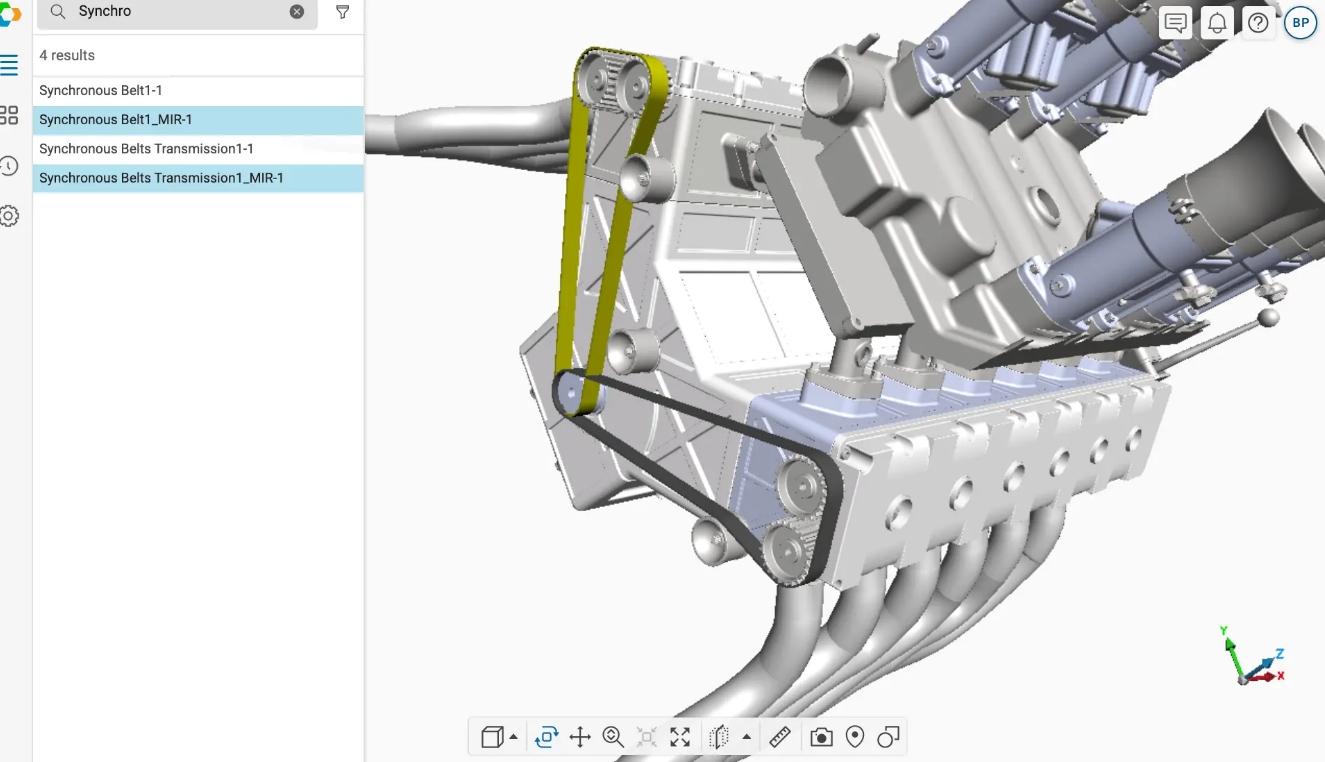

Vertex’s purpose-built software will support John Deere’s Industry 4.0 initiatives, including Smart Connected Factory programs, by providing real-time, actionable 3D data for manufacturing and business operations, adding that their 3D platform significantly reduces the time, cost and effort required to use 3D visualization in the manufacturing value chain. The platform will help John Deere create and deploy fit-for-purpose applications that provide decision-making systems with rich, interactive 3D content.

“For the first time, manufacturers have a truly efficient way to leverage their 3D data assets beyond development,” said Dan Murray, CEO and founder of Vertex Software. “We’re like Netflix for CAD. Now you can connect with everyone, everywhere and instantly with 3D.”

Industry 4.0 is

The Fourth Industrial Revolution (Industry 4.0) involves a new approach to manufacturing based on the massive adoption of information technology in industry, large-scale automation of business processes and the proliferation of artificial intelligence.

The benefits of the Fourth Industrial Revolution are obvious: increased productivity, greater worker safety by reducing jobs in hazardous working conditions, increased competitiveness, fundamentally new products and much more.

“The world is at a crossroads. The social and political systems that saved millions of people from poverty and guided our public and global policies for half a century are now working against us.” With this disturbing assertion begins the book “Technologies of the Fourth Industrial Revolution,” written by Klaus Schwab, founder and permanent president of the World Economic Forum in Davos. In 2016, he coined the term “Industry 4.0” (it originated in 2011 in Germany and denoted “smart factory” technologies), which has become synonymous with the Fourth Industrial Revolution.

Like all previous industrial revolutions, the Fourth is changing not only production, but all of our lives – the economy, relationships between people, even to some extent the very understanding of what it means to be human. Artificial intelligence and robotics, the Internet of Things (IoT) and 3D printing, virtual and augmented reality, bio- and neuro-technologies – these latest methods are becoming part of our everyday existence.