Alternative sources of renewable energy are attracting increasing interest from investors and consumers. The prices of fossil fuels and increasingly restrictive legal regulations regarding their combustion will cause a greater need for substitutes for coal, crude oil or natural gas in the near future. Biomass offers a wide range of possibilities in this area. One of the most energy-efficient plants is miscanthus, which is cheap to grow but unfortunately difficult to harvest. However, John Deere 960 and V451R series balers have done an excellent job at Mariusz Antonow’s plantation in Poland’s Ciesnów, near Opole.

Miscanthus giganteus is a hybrid of two other species, M. sinensis and M. sacchariflorus. It is a clump grass up to 4 meters tall that, after proper establishment and adaptation, has very low environmental and fertilizer requirements, is resistant to pests and diseases, and grows in almost any type of soil. Its yields under favorable conditions can even reach 25 tons/ha.

Miscanthus plantations can last up to 20 years if the soil is properly prepared for cultivation – we are talking about the correct pH of the soil and its organic fertilizer. Because of the large size of the plants, there is more or less 1 plant per m² of surface area. In the first years of growth, provide good moisture and use mulch for frost protection.

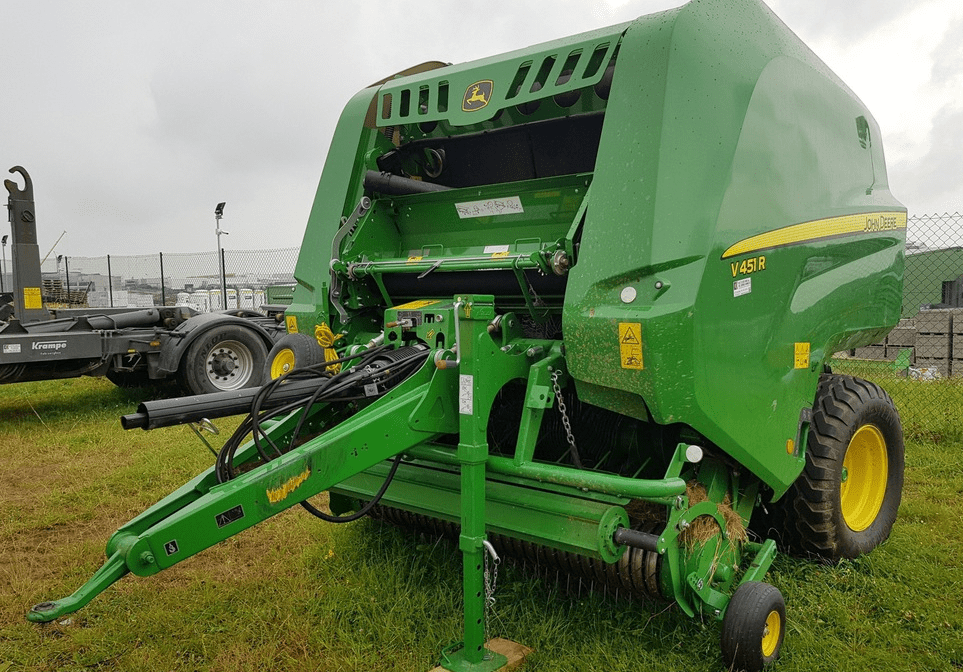

Mariusz Antonow works on a 60-hectare plantation of giant miscanthus in southern Poland, in Prudnitz district. As he points out, harvesting Miscanthus is not easy because of the properties of the grass, which is tough and its panicles contain fatty substances that stick to the working tools of machines. However, through trial and error, a solution was found, which are John Deere balers: the V451R variable chamber and the 960 wrapper version.

With the revolutionary Fast Release System (FRS)

The V451R variable chamber baler with its high-performance 2.2 m wide feed system produces over 120 bales per hour. This machine is equipped with a Premium class cam track pick-up with a very large diameter rotor of 48 cm with shaft-mounted screw conveyors. The traditional design of the scrapers allows in this case to reduce the space between the pick-up fingers and the rotor. According to the farmer, the high quality of the materials used also plays an important role. The baler has proven itself in difficult harvesting conditions, and at the same time, it is reliable and outperforms competitors in its class.

The farmer also appreciated the V451R baler. The R-Series supports Isobus architecture and the baler is easy to set up and operate from the operator’s cab. A video camera lets you see the baling process on the screen in the cab, even at night or in strong sunlight during the day. The efficiency of the baler is always top notch.