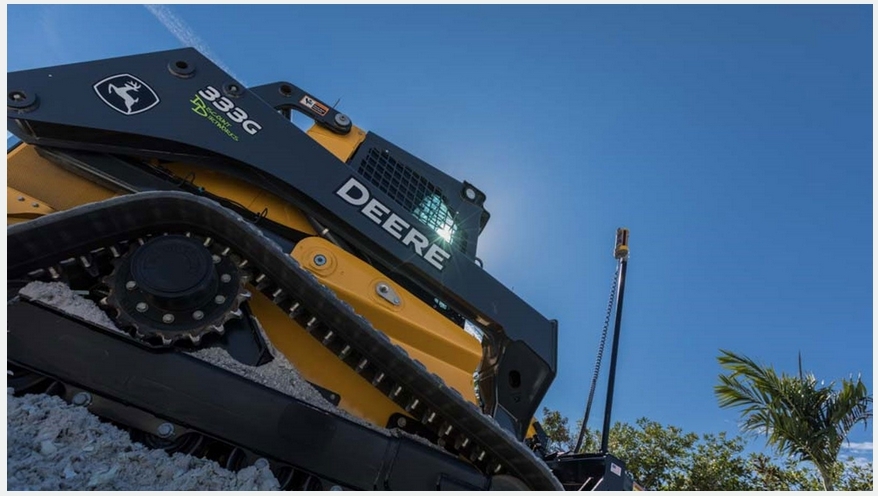

MANAGING TRACK WEAR ON YOUR CTL

Track maintenance is vital to the performance and uptime of your compact track loader (CTL). By training your operators, inspecting and cleaning tracks, and maintaining proper tension, you’ll extend track life and reduce downtime and operating costs.

HANDLE WITH CARE

CTLs excel in soft underfoot

conditions like dirt and mud. If you work primarily on asphalt or

concrete, a wheeled skid steer loader or compact wheel loader might be a

better choice, as these conditions wear the rubber surfaces of a track

at a faster rate. If you must run a CTL on hard surfaces, consider

sprinkling sand or dirt in the machine’s path to reduce track wear.

Train operators to take wide turns instead of counter-rotating like on a

skid steer to help minimize wear. They should avoid spinning the tracks

and go up and down slopes rather than across to reduce wear. In

general, teach them to keep the full length of the tracks on the ground

as much as possible. When going over a curb, they should approach slowly

and in a perpendicular direction to reduce pressure on the tracks and

rollers.

INSPECT AND MAINTAIN

Daily inspection and

maintenance are critical to avoiding premature track and component wear

as well as unnecessary repairs. Check your tracks daily for the

following:

- Examine tracks for caked-on mud and debris. Do not allow mud to dry or freeze in the tracks. Use a shovel or pressure washer to remove material.

- Inspect track tension (see PAY ATTENTION TO TENSION below).

- Look for cuts or tears perpendicular to the tracks, missing chunks, or uneven wear around the sprocket/roller area. If cuts run parallel with the track, it’s usually okay to continue operation for a while, but perpendicular cuts or tears often result in complete failure. Steel or fiber belts run the length of the track similar to a radial tire. If the cords are intact, the track will usually last, but if they are severed, failure is probably imminent.

PAY ATTENTION TO TENSION

Over- or

under-tensioning is the main cause of track failure. A track that is too

loose will wear faster and could even slip off the sprocket, exposing

components to damage. A track that’s too tight causes component wear,

robs the CTL of horsepower, and burns more fuel.

ADJUST TRACK SAG

The track tension on your CTL can be adjusted in a few minutes using a grease gun and a crescent wrench:

- Bring the CTL to a full stop.

- Lower the boom to raise the front end of the tracks approximately eight inches off the ground.

- Remove any debris between the track and the sprocket.

- Locate the third roller from the rear of the machine and measure the distance between the bottom of the roller and the top of the track.

- Check your operator’s manual for track-sag specifications.

- If the track needs adjustment, remove the cover plate located on the undercarriage frame.

- If the track needs to be tightened, connect a grease gun to the grease fitting and add grease until the track idler extends far enough to bring the sag within recommended limits.

- To loosen the track, slowly turn the track-adjuster valve counterclockwise, allowing grease to escape through the bleed hole. Clean any excess grease from the zerk and dispose of it per environmental regulations. When the amount of track sag is satisfactory, turn the valve clockwise to tighten.

- With the track sag within the recommended limits, reattach the cover plate.